MAN trucks are known worldwide for their durability, efficiency, and performance in demanding transport conditions. To keep these vehicles operating safely and efficiently, high-quality MAN truck bearings play a critical role. From wheel hubs to gearboxes and engines, bearings ensure smooth rotation, load stability, and long service life under extreme loads.

What Are MAN Truck Bearings?

MAN truck bearings are precision-engineered components designed specifically for MAN commercial vehicles, including MAN TGA, TGX, TGS, TGM, and TGL series. These bearings are used in various systems such as:

-

Wheel hubs

-

Transmission and gearbox assemblies

-

Differential and axle systems

-

Engine and auxiliary components

They are manufactured to meet strict OEM or OEM-equivalent standards to withstand heavy loads, high speeds, vibration, and harsh operating environments.

Key Features of High-Quality MAN Truck Bearings

1. High Load-Carrying Capacity

MAN trucks operate under constant heavy loads. Bearings designed for these vehicles offer excellent radial and axial load capacity, ensuring stable performance even during long-haul or off-road operations.

2. Superior Wear and Fatigue Resistance

Premium MAN truck bearings are made from high-grade bearing steel with optimized heat treatment. This provides strong resistance to wear, pitting, and fatigue, extending service life and reducing unexpected downtime.

3. Precision Manufacturing

Tight dimensional tolerances and smooth raceway finishes minimize friction and vibration. This improves fuel efficiency, reduces noise, and enhances overall driving comfort.

4. High Temperature and Contamination Resistance

Truck bearings often work in high-temperature environments and are exposed to dust, moisture, and road debris. Advanced sealing designs and specialized lubricants help protect bearings from contamination and premature failure.

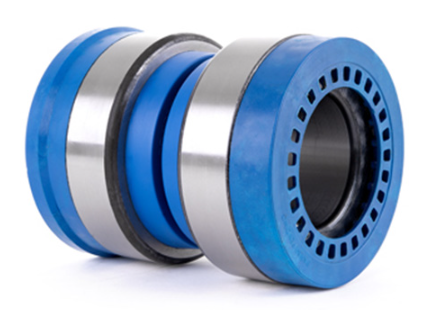

Common Types of MAN Truck Bearings

Depending on the application, MAN trucks use different bearing types, including:

-

Tapered roller bearings for wheel hubs and axles

-

Cylindrical roller bearings for gearboxes and transmissions

-

Ball bearings for auxiliary and engine components

-

Thrust bearings for axial load support

Each type is engineered to match the specific load and motion requirements of the system.

Applications in MAN Commercial Vehicles

MAN truck bearings are widely used in:

-

Long-haul logistics and freight transport

-

Construction and engineering vehicles

-

Mining and off-road trucks

-

Municipal and special-purpose vehicles

Reliable bearings help maintain vehicle safety, reduce maintenance frequency, and ensure consistent performance in all working conditions.

OEM vs Aftermarket MAN Truck Bearings

-

OEM bearings are supplied directly to MAN and meet original factory specifications.

-

Aftermarket bearings from reputable manufacturers offer OEM-equivalent quality with more competitive pricing and wider availability.

Choosing trusted brands and correct part numbers is essential to ensure compatibility and performance.

Maintenance and Replacement Tips

To maximize the service life of MAN truck bearings:

-

Follow recommended lubrication intervals

-

Inspect seals regularly for damage or leakage

-

Replace bearings in pairs where applicable

-

Use proper installation tools and torque settings

Preventive maintenance helps avoid costly breakdowns and extends the lifespan of related components.

Conclusion

MAN truck bearings are vital components that support the reliability and efficiency of MAN commercial vehicles. By selecting high-quality bearings that meet OEM standards, fleet operators and maintenance professionals can reduce downtime, improve safety, and lower total operating costs.

Whether for wheel hubs, transmissions, or engine systems, investing in the right MAN truck bearings ensures long-lasting performance under the toughest working conditions.