Man Truck Bearings

What is a Wheel Bearing?

A wheel bearing is an un-sprung component of a vehicle suspension that is designed to negate the effects of a wheel in motion with friction. A wheel bearing is located at each wheel hub where the car wheel/tire assemblies are located.

*Where Are Wheel Bearings Located?

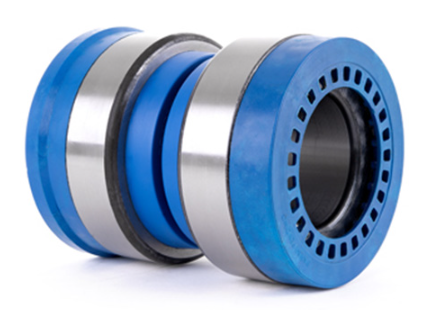

Wheel bearings form a crucial part of the wheel assembly connecting the wheel and axle. There are two different types of bearings (ball bearings or roller bearings), which are held together inside a waterproof, grease-filled, sealed metal ring called a race. These bearings ride on a metal axle shaft that fits snugly inside the wheel hub at the center of the wheel. Some commercial vehicles like trucks have their wheel bearings housed inside the brake disc rotor.

The hub assembly is located between the drive axle and braking components (brake caliper, and brake discs or drums). It incorporates the hub, ABS wheel speed sensor, wheel bearings, and mounting flange. The wheel is held onto the bolts of the wheel hub assembly (on the brake disc side). On the drive axle side, the hub assembly is mounted to the steering knuckle as a press-in or bolt-on assembly. Most modern vehicles have sealed wheel bearing hub assemblies to further reduce rotating friction.,

Each wheel has its own set of wheel bearings to help the wheel rotate with as little friction as possible. The wheel bearings must be tightly packed and able to support the entire weight of a vehicle. Wheel bearings are critical components of a vehicle’s suspension, steering, and braking systems.

*Types of Wheel Bearings: Ball Bearings vs. Roller Bearings

Ball bearings and roller bearings form the two main categories of anti-friction bearings. They have a lot in common with some important distinctions between them.

Both ball bearings and roller bearings are made up of rolling elements and a separator that spaces the rolling elements evenly apart. The separator may also be called a retainer or cage, but no matter the name it’s given, it performs the same function. Both types of bearings have an inner ring, also called an inner race or cone, and an outer ring, also known as an outer race or cup.

Where ball bearings differ from roller bearings is their roller element. As their name implies, ball bearings use balls as rolling elements whereas roller bearings use a cylindrical, barrel, tapered, or needle-shaped element.

Ball bearings and roller bearings both accomplish the same objective, which is to reduce the friction of a rotating mass. But ball bearings are used in applications where they are subject to higher speeds, whereas roller bearings perform better under heavier loads and impact loading. When too much pressure is placed on a ball bearing it is at risk of deforming, The cylindrical design of roller bearings allows them to distribute weight over a larger surface.

How Do Wheel Bearings Break?

As a general rule, wheel bearing failure can occur from general wear and tear throughout a vehicle’s life. In vintage cars, wheel bearings are serviced regularly with automotive grease and a replacement seal, so when maintenance is foregone, failure will occur. But in modern vehicles, the wheel bearings are sealed permanently and are not serviced. They are replaced only when their failure is discovered. However, this does not guarantee that a wheel bearing will never fail. There are many reasons for a wheel bearing failure which are not limited to overloading, collision impacts, and extended mileage.

How Do You Know When Wheel Bearings Go Bad?

When the vehicle is in motion, you may hear a growling noise that coincides with the rotation of the tires. Also, you may feel a vibration in the steering in the case of the front and in the vehicle seat or floor in the case of the rear. That is what usually alerts the driver to a wheel bearing issue. When steering and changing lanes on the roadway, sometimes a change in growling pitch and vibration might be noticed and will alert the driver to a bearing issue as well. In severe cases, a low brake pedal will be due to a wheel bearing issue.

The most common sign of a bad wheel bearing is a grinding noise that changes in conjunction with vehicle speed. It can be misleading to diagnose a bad wheel bearing based on noise alone as a sticking caliper and worn diff gears can be easily confused with wheel bearing noise.

To check if your wheel bearings are bad you’ll need access to a lift. Raise the vehicle off the ground, then grab the tire with your hands on the 9 o’clock and 3 o’clock positions. Rock the wheel back and forth to feel if there is any play or looseness. Place your hands on the 12 o’clock and 6 o’clock positions and repeat the test. On older vehicles with serviceable wheel bearings, a small amount of play is normal.

Different makes of vehicles will have different tolerances (maximum amount of acceptable play). For an accurate reading, sometimes a dial indicator can be used to measure the amount of play in the wheel bearings.

If a wheel bearing is still suspected to be bad but is not showing signs of excess play, the wheel, brake pads, brake calipers, brake discs and bearing assembly will have to be removed to perform a visual inspection on the wheel bearing. A bad wheel bearing will often have small metal shavings present in the grease around the wheel bearing – an indication that the bearings are starting to come apart and in need of replacement.

Signs of a Bad Wheel Bearing

Noise is useful when diagnosing a bad wheel bearing but can’t be relied on as the sole indication due to other issues that can cause similar noises. Other symptoms or signs of a bad wheel bearing can include the following:

ㆍLooseness in steering: This can be described as excessive play in the steering wheel, or vague steering. It can be difficult to describe but your car will feel loose as you drive it and the steering will seem less responsive or precise than usual.

ㆍSteering wheel vibration: You will notice a change in vibration relative to vehicle speed or as the vehicle is turning. You may feel a wobble through the steering wheel.

ABS malfunction: Your ABS warning light may illuminate due to ABS issues related to a failure of the ABS sensor that is integrated into the wheel bearing.

ㆍBraking Issues: When wheel bearings are worn to the point of looseness, there can be a pulsating or pulling of the vehicle when the brakes are applied. This can be accompanied by unevenly worn brake pads.

ㆍCar pulling to one side: Instead of driving where the steering wheel is pointed, the car may feel like it wants to keep veering in a particular direction or wandering.

ㆍTire wear: Even if you rotate your tires regularly, worn wheel bearings can cause noticeably uneven tire wear. As bearings begin they fail, they become loose – a condition known as ‘bearing play’. This isn’t felt through the steering wheel but is detected by visually inspecting the tires.

Man Truck Bearings

*How Much Does a Wheel Bearing Replacement Cost?

The cost of a front wheel bearing replacement varies greatly among vehicle applications. Typically an estimate on a front wheel bearing repair for a domestic front-wheel drive car will be from $250 to $400.

Asian imports in the years of 1980s to early 2000s would be pricier at $300 to $400 because of a two-piece hub and bearing design that will require higher part and labor costs. Modern rear-wheel drive light trucks carry a price of a front wheel bearing replacement of $300 to $400. European imports generally will estimate at a $400 — $600 replacement cost because of parts costs being higher.

Rear-wheel bearing replacements are a different story. Front-wheel drive vehicles have rear bearings that are not connected to the axle and drivetrain mechanism. They are easily replaced as a bolt-on assembly and estimate at $100 — $200 in most applications. Rear-wheel drive vehicles such as light trucks have wheel bearings that are pressed fit to the rear axle housing or onto the axle themselves.

Repairs on rear-wheel drive bearings require more extensive labor time because of extra steps that are involved in the process. Many Toyota and Nissan light trucks can estimate out at over $1,000–1,200 for rear axle bearing replacements.

What Happens If I Don’t Replace Bad Wheel Bearings?

Ignoring wheel bearing issues can affect braking performance. A low brake pedal feel is caused by a misalignment of the brake rotor to the brake caliper when severe failure is imminent. Also, a potential loss of steering control can develop if faulty wheel bearings are not replaced because a change in vehicle camber and toe will cause unstable tracking and handling when driving. Finally, in some extreme cases, a bad wheel bearing can cause the wheel/tire assembly to come off of the vehicle, potentially leading to an accident.

*Can I Drive with a Bad Wheel Bearing?

It’s rare for wheel bearings to render a car undrivable immediately after you notice the first signs that they’re going bad. But despite that, it’s best to avoid driving a car with worn wheel bearings as much as possible. If you suspect that a wheel bearing is showing signs of wear, have it inspected immediately rather than risk losing control of the vehicle or causing further damage.

If you do drive a car with a worn wheel bearing you will notice the steering feels loose and wobbles excessively. This reduces steering responsiveness, making the car extremely unsafe – particularly when driving in traffic.

As the wheel bearing is essential for keeping the wheels connected to the car, a weak point can compromise drive-axle, braking, and steering operation. Additionally, it causes additional stress on the wheel hub and CV joints.

A car with worn wheel bearings is not safe to drive for any length of time. But if you are in an unsafe situation and there is no other option but to drive your car, it must be done with extra care, with the driver following these pointers:

ㆍDrive as slowly as possible, at a steady speed

ㆍKeep off highways and avoid heavy traffic

ㆍTurn slowly

ㆍApply brakes with care

ㆍDrive only in fair weather

We never recommend driving a car with a worn wheel bearing.

*How Long Can I Drive with Bad Wheel Bearings?

When asked, it’s not uncommon for some mechanics to claim you can drive up to 1,000 miles with a bad wheel bearing. This distance is a meaningless number probably plucked out of thin air. It’s impossible to know how worn a set of wheel bearings is without inspecting it, and even then it can be difficult to predict how long you can keep driving before it disintegrates.

Some mechanics may give you a time estimate but it’s important to note that it is exactly that – just an estimate. There is no way that anyone can tell how long it’s safe to drive your car with bad or worn wheel bearings.

The only time it may be acceptable to drive with a worn wheel bearing is if you are far from home or a mechanics workshop, and it’s unsafe for you to stay where you are. In this instance, the car should be driven as slowly as possible to avoid generating excess heat or causing further complications.

In any conceivable circumstance, driving a car with a worn bearing is extremely dangerous, and should only be considered in the event of an emergency. Driving a car with a worn wheel bearing can put additional stress on the wheel hub, the transmission, and the CV joint, and driving a car in this state is simply pushing your luck.

What Do Bad Wheel Bearings Do to Your Car?

Driving a car with a bad wheel bearing is technically possible, but to do so is pushing your luck, and wheel bearings that are worn, seized, or missing can cause a cascade of additional problems.

At the more serious end of the scale, a wheel bearing that is left to wear down is at risk of seizing and locking your vehicle’s axle. This is definitely something you don’t want to happen when driving, and if it does, the car cannot be driven or moved.

Wheel bearings form part of a mounting point and are essential for keeping wheels connected to the car so any weakness can have serious consequences for both the drive-axle and steering assembly. If a bearing is showing signs of serious wear, it could loosen the entire wheel assembly, and in some cases, entire wheels and tires have fallen off while the vehicle is in motion.

A bad wheel bearing can also cause brake rotors to wobble, reducing braking performance and as you know, anything that affects braking performance can make a car downright dangerous to drive. At the very least, a bad wheel bearing will cause uneven tire wear and be responsible for tires wearing out faster than they normally would.

Do Wheel Bearings Differ by Type of Car?

Essentially, the symptoms are universal to almost all vehicles. The only difference would be variability in repair costs.

Can Wheel Bearings be Serviced?

Wheel bearings need periodic checking and depending on the type of wheel bearings in your car, there are a variety of service options. Wheel bearings most commonly fail for the following reasons:

ㆍMisadjustment

ㆍContamination

ㆍLoss of grease

ㆍFatigue spalling

Wheel bearings on most modern cars sit inside a sealed hub assembly that is mounted inside the steering knuckle. These sealed bearings are maintenance-free, but if a sealed bearing has gone bad there is no other option but to replace it. The average lifespan of sealed bearings is typically anywhere from 80,000 to 120,000 miles. Sealed bearings are more expensive than serviceable bearings, but they come prepacked with grease and don’t require regular maintenance.

In the case of a serviceable bearing (one that isn’t sealed), the seals are the bearing’s weakest point and are vulnerable to leaking. Once a seal is damaged, it can cause grease to leak out and water and dirt to leak inside the bearing cavity.

In older vehicles, the seal can be replaced to extend the life of the bearings. When serviceable bearings are subject to water, mud, or consistently harsh elements, they may need to be regreased and repacked. It’s generally recommended to have serviceable wheel bearings repacked with grease at around 40,000 miles.

Can I Replace Wheel Bearings by Myself?

Generally, front-wheel bearings are replaced as a hub/bearing assembly, meaning no extra parts will be necessary. Only if extended use has damaged the brakes, a replacement of pads and rotors may be needed. However, in the case of rear wheel bearings, there are many other variables that can be uncovered after inspection. Rear brake pads/linings can be contaminated with axle lubricant. Rear axle bearing housings, races, seals, axle fluid, and axles themselves may become casualties too. A proper inspection will uncover any further cost issues regarding rear wheel bearings.

Are There Any Ways to Save on Cost?

With some applications, a bargained price wheel hub/bearing may be available from auto parts discounters. But remember that a shorter part warranty time period may accompany it, and generally it is not recommended to take that route. The best way to make a wheel bearing repair cost less is to have the vehicle serviced and inspected on a regular time and mileage schedule so that potential wheel bearing issues can be discovered before the costs get too catastrophic.

We are a truck bearing manufacturer. If you are interested in our products, please contact us now!