The more your shop knows about wheel hub bearings, the better you can serve your customers. Below, you'll find 5 common questions technicians have about wheel hub bearings.

1. Can Potholes Really Cause Severe Wheel Bearing Damage?

Short answer, is yes. Under normal circumstances, wheel bearings last a long time. Yet, potholes can do quite a number on bearings. Potholes can cause a small indentation in the bearing races. When that happens, the bearings get hung up in the depression in the race. That means the wheel bearing can't rotate as freely anymore. In addition, the bearing now has slightly more slop. Over time, the problem gets worse and worse.

It's important to be able to pinpoint why the wheel bearing was damaged. Potholes are one of the most common, yet overlooked, causes of wheel bearing damage. Here's a list of signs that indicate possible pothole damage to the wheel bearing:

Clunking noise

Rattling noise

Shaky steering wheel

Wobbly wheel

Poor alignment

Tire marks on the wheel well

Damaged bump stops

Wheel damage (cracks or dents)

2. How Can I Make Sure The Air Gap For A Wheel Speed Sensor Is Correct After Installing A Bearing?

It's important to keep the right distance (air gap) between the end of a wheel speed sensor and its ring. If the gap is too wide, the signal won't be strong or reliable. It'll be weak, erratic, or nonexistent. If the gap is too close, there may be some metal-to-metal contact.

When you install a new wheel bearing, the wheel speed sensor gap might change. When this happens, the ABS light will come on in the customer's car after they leave your shop. To prevent this from happening, check the wheel sensor gap after installing a wheel bearing. To do this:

Attach a voltmeter to the wheel speed sensor's terminals.

With your hand, spin the tire at a rate of about 1 revolution per second.

Check the reading on the voltmeter. If the air gap is correct, the wheel speed sensor will generate between 50 and 77 millivolts AC. If the output is low, or if there's no output, the gap may be too wide.

3. Can Bad Alignment Angles Like Camber And Toe Cause Premature Failure Of A Wheel Bearing?

Yes. A bad alignment angle can cause a wheel bearing to fail. If the vehicle is out of alignment, the driver has to keep the steering wheel turned slightly to keep the car going straight. This adds stress to the wheel bearing, and ultimately causes the bearing to wear down faster.

4. How Should Surfaces On Axles And CV Joints Be Cleaned Or Polished Before A Bearing Is Replaced?

When replacing a wheel bearing, it's good practice to clean or polish the bearing surfaces on axles and CV joints. It's to help extend the life of the axles and CV joints. By cleaning those parts, you would be removing sludge, metal shavings, and any old differential oil that has been sitting there for a while.

The proper way to clean or polish those parts is to:

Remove those parts from the vehicle.

Cover the surfaces with brake cleaner or another degreaser.

Wipe down the surfaces with a dry shop rag until clean.

If you find any hardened grease stuck on the axle, scrub it with a non-metallic scrubbing pad and degreaser.

5. What Is The Proper Inspection Method For A Seal?

You can visually inspect the wheel bearing seal. Grab a flashlight and then inspect it for:

Leaks

Cracks

Twists

Breakage

Sometimes the cracks are so fine that they are difficult to see. It takes a little patience to do a thorough inspection.

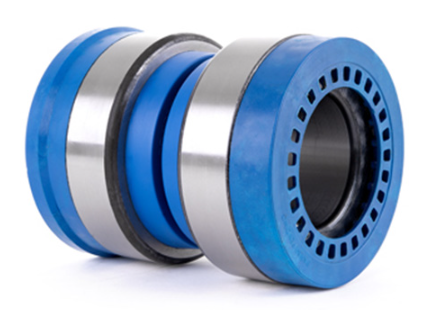

We are a Truck Hub Bearing supplier. Please feel free to contact us if you need them!