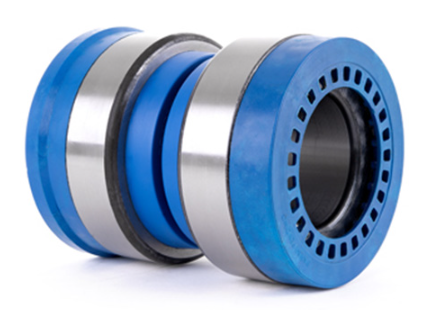

Wheel end hub unit

Bearings fit into the hub of your wheels and they are what allows your wheels to turn properly. Truck wheel bearings carry the entire weight of the truck so repacking your truck bearings is a critical part of your regular truck maintenance.

Bearings require grease to prevent friction and ensure the wheel turns freely but over time the grease starts to break down. If your bearings are not kept well-greased the increased friction will eventually cause your wheel to seize.

If this happens while you are hauling, it will not only leave you stranded roadside, but it will also cost you a lot of money in truck repairs. Furthermore, if your bearings seize or fail at a high rate of speed it can put you and others at risk of a serious accident.

How can you tell when your bearings start to fail?

1) Sound

You will hear a screeching, grinding, or roaring sound coming from your tires in motion

2) Tire Movement

If you grab your tire with both hands and you are able to move it up and down more than normal this could be a sign that it is time for some bearing maintenance.

3) Steering Abnormalities

If you feel your truck start to veer to one side consistently or there is more play in your steering than there should be then it is likely that it is time to repack or replace your bearings.

Truck bearing

How often should truck wheel bearings be repacked?

The axle manufacturers recommend that you repack your truck bearings once annually or every 12,000 km.

If you are over-do truck wheel bearing maintenance, we would be happy to help you. All of us here at Qianyu Auto Parts want to make sure that every trip you take with your truck is a safe and uneventful one!

How much does it cost to repack a wheel bearing?

In a car, it will cost between $100 and $400 on average to have your bearings checked, repacked, or changed professionally (depending on your location and mechanic). Some servicers will provide these optionally during break tune-ups; others do not. Trucks tend to be cheaper to repack professionally (think $100-$200), but don't underestimate the power of the upsells a mechanic might try to give you.

If you're serious about cash, you can likely save a few bucks by repacking your bearings yourself. However, the tradeoff is a few hours of your time to learn and do the procedure, and a probable lack of experience in doing so. You stand to save a considerable amount of money if you do it right though - just make sure you know what you're doing. Best case scenario: find someone who has done it before and ask them to show you how it's done!

Whether you choose to use a professional or do it yourself, weigh the pros and cons of each option carefully before making your decision. We are a high-end auto bearing manufacturer from Shandong. If you are interested in our products, please contact us now!