A worn wheel hub bearing is a pretty big deal. If you let it go on long enough, the wheel could literally fall off while you're driving. That could cause a catastrophic accident that puts your life and others' lives at risk. That's why it's important to watch out for the signs of a worn wheel hub bearing.

We put together a comprehensive list of telltale signs of a worn wheel hub bearing. Read on to find out what they are.

1. Unusual Noises

“Unusual noises” is quite vague, but for a good reason. There are many, many unusual noises associated with a worn wheel hub bearing. Some of the most common noises include:

Knocking/Clunking Noise While Turning

When a wheel hub bearing wears out, it puts extra stress on the CV-joint. That can cause the knocking/clunking noise when you turn the vehicle.

Crackling Noise

The crackling noise is a result of a worn or damaged outer CV-joint. It may also mean excessive bearing endplay due to poor clamping.

Rumbling/Growling Noise

This noise is particularly prominent when the vehicle is traveling in a straight line. It gets worse when the vehicle is turning slightly at a speed of 15-50 mph. In a normal situation, you can pinpoint the problematic wheel bearing if you hear this noise. In most cases, the bad bearing is the cause of the rumbling noise.

Grinding Noise

If you hear a grinding noise, that means there's a loss of integrity in the steering or suspension system. For instance, there may be roller or raceway damage. When you have a worn wheel hub bearing, this noise is prominent when the vehicle is turning.

If you're hearing unusual noises, this guide will help you determine which wheel hub is bad.

2. Vehicle Pulling To The Side When Brakes Are Applied

Worn bearings become loose. As a result, excessive runout happens. This causes the brakes to pulsate or pull. In other cases, a corroded or pitted bearing transmits the vibration through the steering. This can cause pulling to one side, too. Your vehicle will pull to the side of the failed wheel bearing.

3. Loose Steering Wheel

When a wheel hub bearing goes bad, you may feel some looseness in the steering wheel. When a bearing wears down, it becomes loose within the wheel hub and spindle. This will make your steering wheel feel loose.

4. Wheel Vibration And Wobble

When your wheel is vibrating and/or wobbling, the bearing is very loose. It's because the bearing has lost its clamp. There may be some severe mechanical damage, too.

5. Uneven Tire Wear

This happens when the wheel bearing becomes bad enough. Most likely, you will hear noises before uneven tire wear happens. A worn wheel bearing makes the wheel loose. This causes the tire to wear out unevenly.

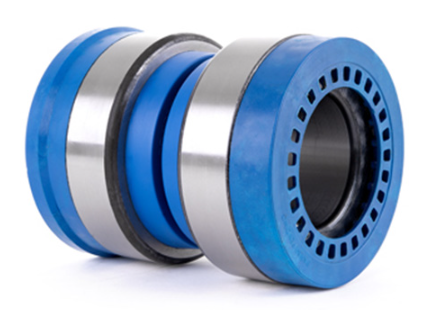

The Importance Of Using A High-Quality Replacement Wheel Hub Assembly

When it's time to replace a wheel hub assembly on a vehicle, it's important to use a high-quality replacement unit. This post has 3 great reasons to avoid using a cheap, low-quality wheel hub assembly.

Qianyu Auto Parts Co., Ltd. is a professional truck bearing manufacturer with more than 20 years of experience in a truck bearing manufacturing. The products have passed ISO/TS16949, ISO9001, EU CE certification, and other certificates, and the quality is reliable. Approved by customers in more than 50 countries. Contact us for a quote!